HP Graphite Electrode rau Steelmaking EAF. Dia.450-500 hli (Nti 16 ″ - 20 ″)

Cov Khoom Muag Khoom Ntse

Khoom npe: HP Qeb Graphite Electrode

Qhov chaw ntawm Keeb Kwm: Hebei, Suav

Hom Lub Npe: Rubang Carbon

Tus Qauv Zauv: RB-HP-I2

Hom: Graphite Electrode

Nipple: 3TPI / 4TPI

Cov Khoom Siv Raw: Rab Koob Roj Roj Coke

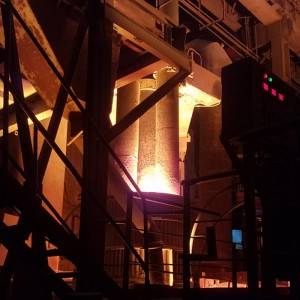

Daim Ntawv Thov: EAF lossis LF ntawm Kev Ua Hlau lossis Smelting Hlau

Ntev: 1800 ~ 2100mm

Qhov Zoo Tshaj: Tus Nqi Siv Tau Tsawg

Xim: Dub

Qib: RP (Fais Fab Los)

Tshuaj lom neeg muaj pes tsawg leeg:

Cov Pa Roj Quav 99% Min Cov Hluav Taws Xob Sib Tw 0.3% Max. Tshauv 0.3% Max.

Cov yam ntxwv ntawm lub cev:

Kev tawm tsam (μΩ.m): 5 - 7

Pom Qhov Txawv (g / cm³): 1.62 - 1.75 g / cm3

Thermal nthuav dav: 1.1 ~ 1.5 X10-6 / (100-600 ℃)

Kev Ua Tau Zoo (Mpa): 8-12 Mpa

Elastic Modulus (GPa): .8.50 ~ 15.50

Muaj Peev Xwm Nqa Tam Sim No: 21-48KA

|

HP & Hom II Graphite Electrodes-Physical thiab Chemical Index |

|||||||

|

Kev piav qhia |

Hom |

Chav Nyob |

Nom phaj Txoj kab uas hla (hli) |

||||

|

Graphite Electrode HP |

Graphite Electrode Hom II HP |

||||||

|

Ø200-400 |

Ø450-500 |

Ø550-600 |

Ø350 - 400 |

Ø450 - 500 |

|||

|

Hluav Taws Xob Kuj (≤) |

Txheeb hluav taws xob |

.m |

7.0 |

7.0 |

7.0 |

6,5 |

6,5 |

|

Txiv mis |

6.0 |

6.0 |

5.8 |

5.5 |

5.5 |

||

|

Lub zog Tensile (≥) |

Txheeb hluav taws xob |

Mpa |

10.0 |

10.0 |

10.0 |

10.0 |

10.0 |

|

Txiv mis |

14.0 |

14.0 |

16.0 |

16.0 |

16.0 |

||

|

Young Cov Qauv (≤) |

Txheeb hluav taws xob |

Gpa |

12.0 |

12.0 |

12.0 |

14.0 |

14.0 |

|

Txiv mis |

16.0 |

16.0 |

16.0 |

18.0 |

18.0 |

||

|

Ceev ntau (≥) |

Txheeb hluav taws xob |

g / cm3 |

1.62 |

1.62 |

1.62 |

1.64 |

1.64 |

|

Txiv mis |

1.75 |

1.75 |

1.75 |

1.75 |

1.75 |

||

|

CTE (≤) |

Txheeb hluav taws xob |

X 10-6/ ℃ |

2.4 |

2.4 |

2.4 |

2.4 |

2.4 |

|

Txiv mis |

2.2 |

2.2 |

2.2 |

1.6 |

1.6 |

||

|

Tshauv (≤) |

- |

% |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

| Nco tseg: Cov ntoo tshauv thiab Thermal Expansion co yog cov cim ntsuas cua. | |||||||

Cov khoom lag luam:

Graphite Electrode yog ua los ntawm cov ntaub ntawv zoo tsis tshua muaj cov ntoo tshauv, xws li roj av coke, koob coke thiab thee suab.

Tom qab Raw Khoom calcining, crushing, tshuaj ntsuam, tsim txom, kneading, sib sau, ci, impregnation, graphitization thiab ces precision tshuab nrog kev CNC machining.

xws li cov khoom lag luam tus yam ntxwv nrog tsis kam, muaj hluav taws xob zoo hluav taws xob, tsis tshua muaj tshauv, compact qauv, zoo tiv thaiv oxidation thiab siab zog lub zog, yog li nws yog qhov zoo tshaj plaws khoom siv rau hluav taws xob arc rauv taws thiab smelting rauv.

Daim ntaub ntawv:

1. Rau Cov Cov Chav Dav Hlau

2. Rau Hluav taws xob arc rauv taws ua hlau

3. Rau cov phosphorus daj cua sov

4. thov rau Industrial silicon rauv taws los yog yaj tooj liab.

5. Ua ntawv rau Ua kom zoo siab hlau hauv qhov cub tawg thiab hauv lwm cov txheej txheem zom

Kev Mob Lag Luam thiab Cov Lus:

Cov nqi thiab cov ntsiab lus xa tuaj: FOB, CFR, CIF, EXW, DDP

Kev Them Nyiaj: USD, EUR, JPY, CAD, CNY, AUS

Cov ntsiab lus them nqi: T / T, L / C, D / PD / A, Western Union, Nyiaj Ntsuab

Chaw thau khoom chaw nres nkoj: XINGANG LOSSIS QINGDAO, CHINA

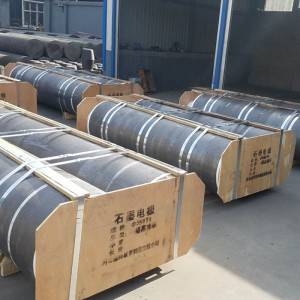

Cov lus qhia pob:

Ntim rau hauv cov thawv ntoo / lathing thiab khi nrog hlua tswj hlau.

Cov Khoom Thauj Khoom Siv thiab Khoom Taw Qhia:

(1) Cov tshuab hluav taws xob yuav tsum khaws cia hauv qhov chaw huv, qhuav thiab tsis txhob muaj kev co thiab sib tsoo. Nws yuav tsum qhuav ua ntej siv.

(2) Thaum txhim kho qhov kev sib koom tes, thov ntxuav lub qhov nrog lub zog cua, tom qab ntawd ua tib zoo ntsia hlau rau qhov sib koom tes thiab tsis puas xov.

(3) Thaum txuas cov electrodes, ob lub tshuab hluav taws xob yuav tsum tau ntxuav nrog cov cua nrawm thaum lawv 20-30 hli sib nrug.

(4) Thaum siv cov ciaj ntswj los txuas rau cov electrode, nws yuav tsum taut zoo rau txoj haujlwm tshwj xeeb kom qhov sib txawv ntawm ob lub electrodes tsis tsawg dua 0.05 hli

(5) Txhawm rau zam qhov hluav taws xob tawg, thov zam qhov thaiv rwb thaiv tsev.

(6) Txhawm rau zam qhov hluav taws xob ua kom tawg, thov tso cov thooj rau hauv qhov kawg.